Email Address

info@magnotest.com

Phone Number

(+967) 123456789

Our Location

UAE

info@magnotest.com

(+967) 123456789

UAE

Enhance your inspection accuracy with high-performance Magnetic Particle and Dye Penetrant products. Trusted by professionals for quality, consistency, and compliance.

All our products meet or exceed global standards for non-destructive testing.

Whether you're conducting critical inspections in aerospace, automotive, manufacturing, or construction, Magnotest is your trusted partner for dependable NDT materials.

Test with Confidence. Inspect with Clarity.

Supplying industry-grade products for Magnetic Particle and Dye Penetrant Inspection—engineered for safety, performance, and peace of mind.

For magnetic particle inspection

For magnetic particle inspection (MPI)

Promo 15% Off

Cleaner/Remover - PT-1

Developing Agent - PT-3

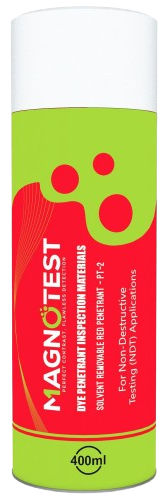

Solvent Removable Red Penetrant - PT-2

For magnetic particle inspection

At Magnotest, we are committed to supporting quality, safety, and precision across industries by supplying top-tier materials for Non-Destructive Testing (NDT). With a focus on Magnetic Particle Inspection (MPI) and Dye Penetrant Inspection (DPI), our products are trusted by professionals for their reliability, consistency, and compliance with international standards.

High-sensitivity magnetic inks and contrast agents designed for accurate detection of surface and near-surface flaws in ferromagnetic materials.

A high-performance contrast enhancer used to improve the visibility of magnetic particle indications. MT-1 delivers sharp, clear indications on light or reflective surfaces, increasing inspection accuracy and reliability.

An oil-based magnetic particle suspension ideal for detecting surface and slightly subsurface defects in ferromagnetic materials. MT-2 provides high sensitivity and excellent particle mobility, ensuring reliable flaw detection during magnetic particle inspection.

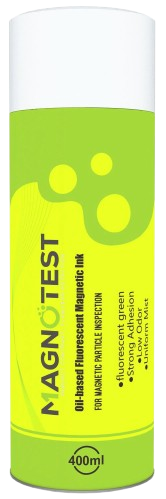

Specially formulated for fluorescent magnetic particle inspection under UV light. This ink offers outstanding brightness and clarity, ideal for low-light environments or applications requiring enhanced visual contrast.

Reliable penetrants, developers, and removers formulated to reveal surface-breaking defects in non-porous materials with clarity and precision.

A versatile solvent-based cleaner designed to prepare surfaces before penetrant application and remove excess penetrant after inspection. PT-1 ensures thorough surface cleanliness, improving DPI accuracy.

A visible dye penetrant used for detecting surface-breaking defects in non-porous materials. PT-2 offers excellent penetration, high visibility, and is easily removable with PT-1 cleaner for efficient inspection workflows.

A fast-drying, white developer that enhances flaw visibility by drawing penetrant out of surface cracks. PT-3 provides a contrasting background for red penetrants, helping inspectors identify even the finest indications with ease.

Trusted by NDT professionals across industries, our products deliver proven results in the field. Here’s what our customers have to say about their experience with us.

Their black magnetic ink and contrast agent have noticeably improved our defect detection process. Highly recommended for anyone in NDT.

Aerospace Manufacturing

The dye penetrant materials are top-notch—easy to apply, clean removal, and excellent flaw visibility. It’s everything we need for reliable DPI testing.

Shipbuilding Industry

We’ve been using their MPI products for over a year, and the consistency is unmatched. The clarity of indications makes inspections faster and more accurate.

Oil & Gas Sector

Great customer support, fast delivery, and products that perform exactly as expected. We trust them for all our NDT material needs.

Accurate, reliable flaw detection that supports high-quality inspections and confident decision-making.

Clean the surface thoroughly using PT-1 Cleaner/Remover to eliminate oil, dirt, and contaminants that can interfere with detection accuracy.

For MPI, apply MT-1 Contrast Agent followed by MT-2 Black Magnetic Ink or Fluorescent Magnetic Ink under magnetization. For DPI, apply PT-2 Red Penetrant and allow dwell time for it to seep into flaws.

In DPI, remove excess penetrant with PT-1. In MPI, ensure magnetic particles have settled properly. The surface should now be ready for indication development.

Apply PT-3 Developer (for DPI) to pull trapped penetrant to the surface and provide contrast. Use visible light or UV light to reveal flaw indications clearly and accurately.

Welcome to WordPress. This is your first post. Edit or delete it, then..

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusm tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam quis nostrud exercitation ullamco laboris.

Lorem ipsum dolor sit amet consectet adipiscing elit sedo.

Lorem ipsum dolor sit amet consectet adipiscing elit sedo.

Inspection EngineerAutomotive Components